LEVAPOR is an innovative biocarrier presenting high adsorbent capacity and affinity to microbial cells.

LEVAPOR delivery form (20 x 20 x 7 mm)

LEVAPOR cross section

Why choosing LEVAPOR biocarrier for aquaculture?

LEVAPOR biocarrier offers several benefits:

- Proved technology in aquaculture,

- High surface resulting in smaller footprint and lower energy consumption,

- Short start-up period,

- High process stability,

- Better utilisation of O2 by longer retention of air bubbles within the pores,

- Mechanical biofilm protection by colonizing inner pore surfaces.

AQUA CONCEPT supports its clients in designing the bioreactor to reach the best performance of using LEVAPOR biocarrier.

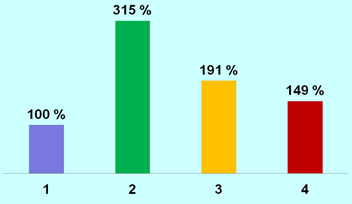

Comparison with biocarriers available on the market?

- Influence of various carrier materials on biological removal of N-NH4 and N-NO2 in RAS:

1-Polypropylene

2-LEVAPOR

3-Polyurethane

4-Ceramics

Technical specification

|

Shape: |

Cuboïdes |

|

Composition: |

PU foam cubes and PAC |

|

Dimensions (mm): |

20 * 20 * 7 |

|

Dump weight (kg/m³): |

26 – 28 |

|

Porosity (%): |

90 - 95 |

|

Water uptake (% b.wt.): |

ca. 250 |

|

Total surface (m2/m3): |

2’700 |

|

Microbial colonisation (min): |

120 – 180 |

|

Required reactor filling (%): |

30 - 35 |

Safety

Harmless and neutral.

Packing

Bag with dimensions 1.1 x 1.1 x 1.8 m (maximum 5 m3 per bag).

Specyfikacja techniczna

| Shape: | Cuboïdes |

| Composition: | PU foam cubes and PAC |

| Dimensions (mm): | 20 * 20 * 7 |

| Dump weight (kg/m³): | 26 – 28 |

| Porosity (%): | 90 - 95 |

| Water uptake (% b.wt.): | ca. 250 |

| Total surface (m2/m3): | 2’700 |

| Microbial colonisation (min): | 120 – 180 |

| Required reactor filling (%): | 30 - 35 |

Bezpieczeństwo

Nieszkodliwy i neutralny

Pakowanie

Worek o wymiarach 1,1 m x 1,1 m x 1,8 m (maksymalnie 5 m3 na worek).